TSC Puralloy® Comsol (LS4) is a high melting point leaded solder alloy compromising of Sn5 / Pb94 / Ag1 (Tin, Lead and Silver). As with many high temperature solders, this alloy does contain lead, however the addition of tin and silver ensure the melting point is lower than pure lead, whilst enhancing the hardness and general fatigue properties. This alloy is ideal for soldering or joining Copper, Brass and Tin.

TSC Puralloy® Comsol (LS4) alloy is ideal for applications where the working temperature is too high to allow the use of standard Sn/Pb and Sn/Ag alloys. Typical applications would be for transformer bobbins, general electrical motors repairs, boiler repairs together with securing components which are required to be unaffected by a subsequent reflow or wave soldering operation. Model engineers would look to use this alloy to repair any porosity in steam boilers previously soldered with hard silver solder alloys.

Key Features & Benefits:

– Leaded Solder Alloy.

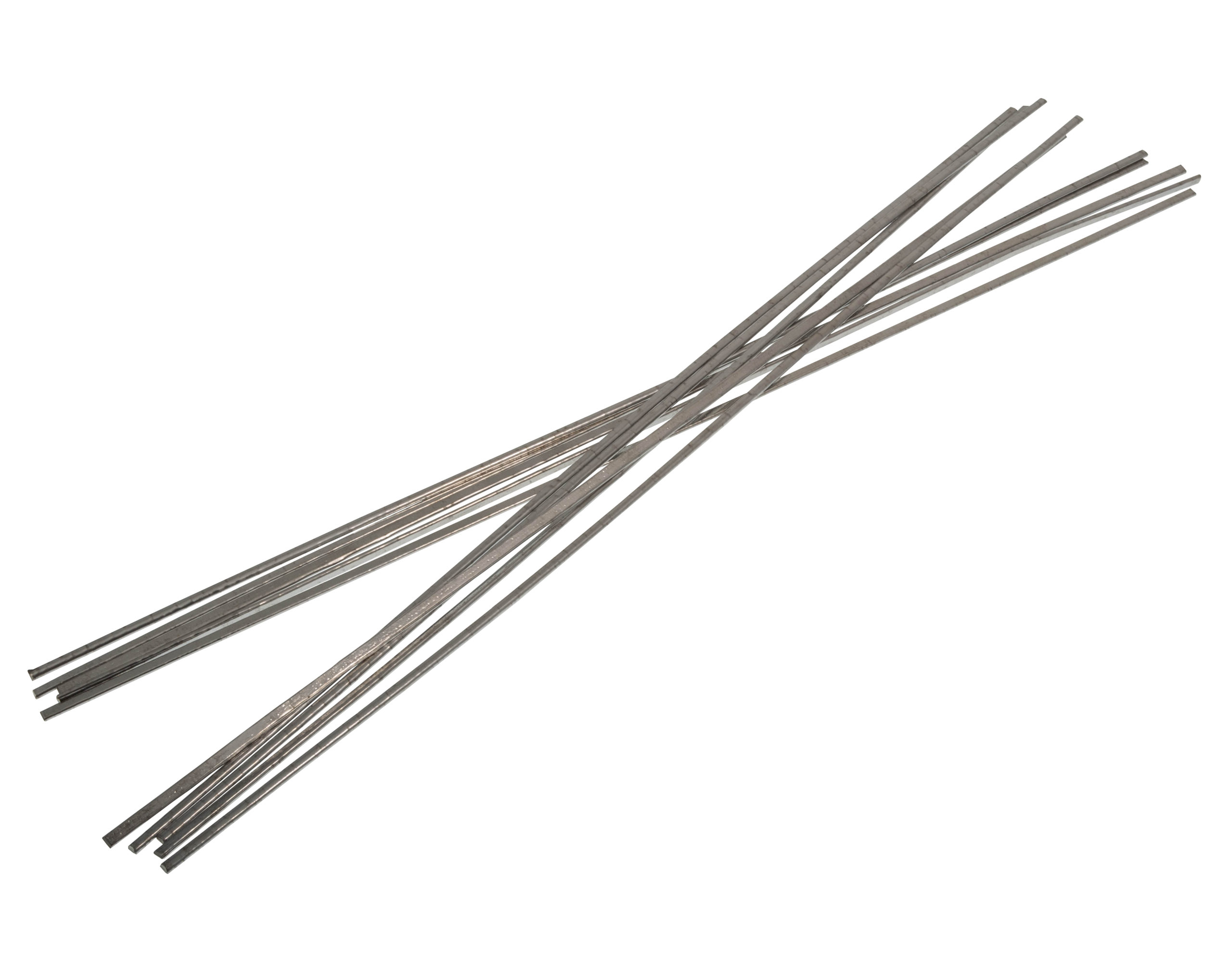

– Approx 3.5mm Diameter

– Melt Point – 294 – 305°C.

– Designed for high temperature hand and dip soldering techniques.

– Can be used at temperatures up to 450°C.

– Minimal drossing levels, reduces production down time.

– Ideal for step soldering.

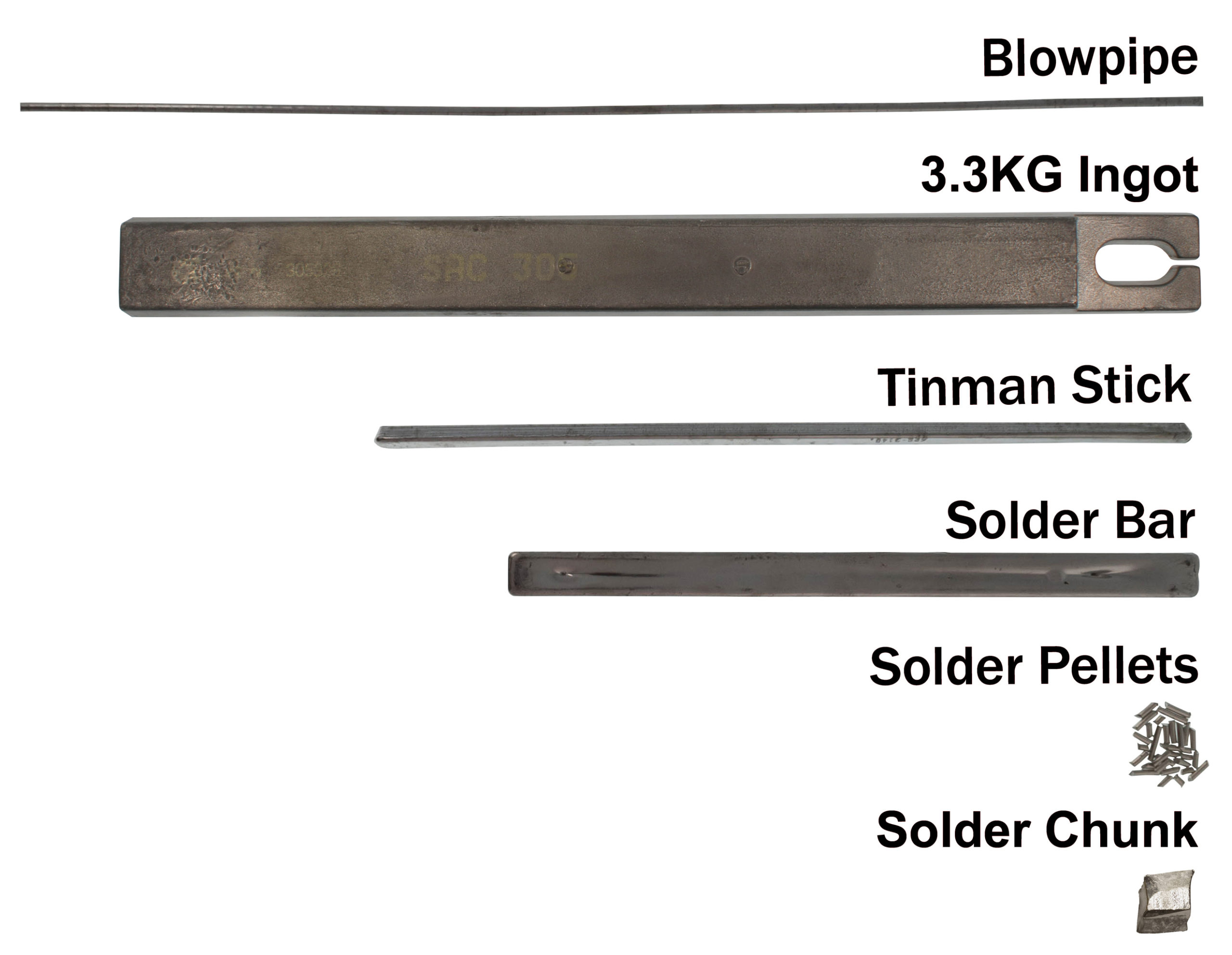

– Excellent fatigue properties – Available in a range of formats including Bar, Tinman Sticks, Blowpipe and Feed Wire.

Reviews

There are no reviews yet.