Limited Time Offer!

FREE MicroFine Upgrade Kit with purchase of MX-5210 or CV-5210. Click here or contact our Sales Office for more information.

Metcal innovation has led the industry for decades, beginning with SmartHeat technology that senses the thermal load and instantly delivers Power on demand to the solder joint. The embedded self-regulating heater delivers the right amount of Power based on the requirements of the solder joint. This provides a fast, safe, and repeatable process with no calibration required. The intermetallic compound thickness is critical in the formation of a solder joint.

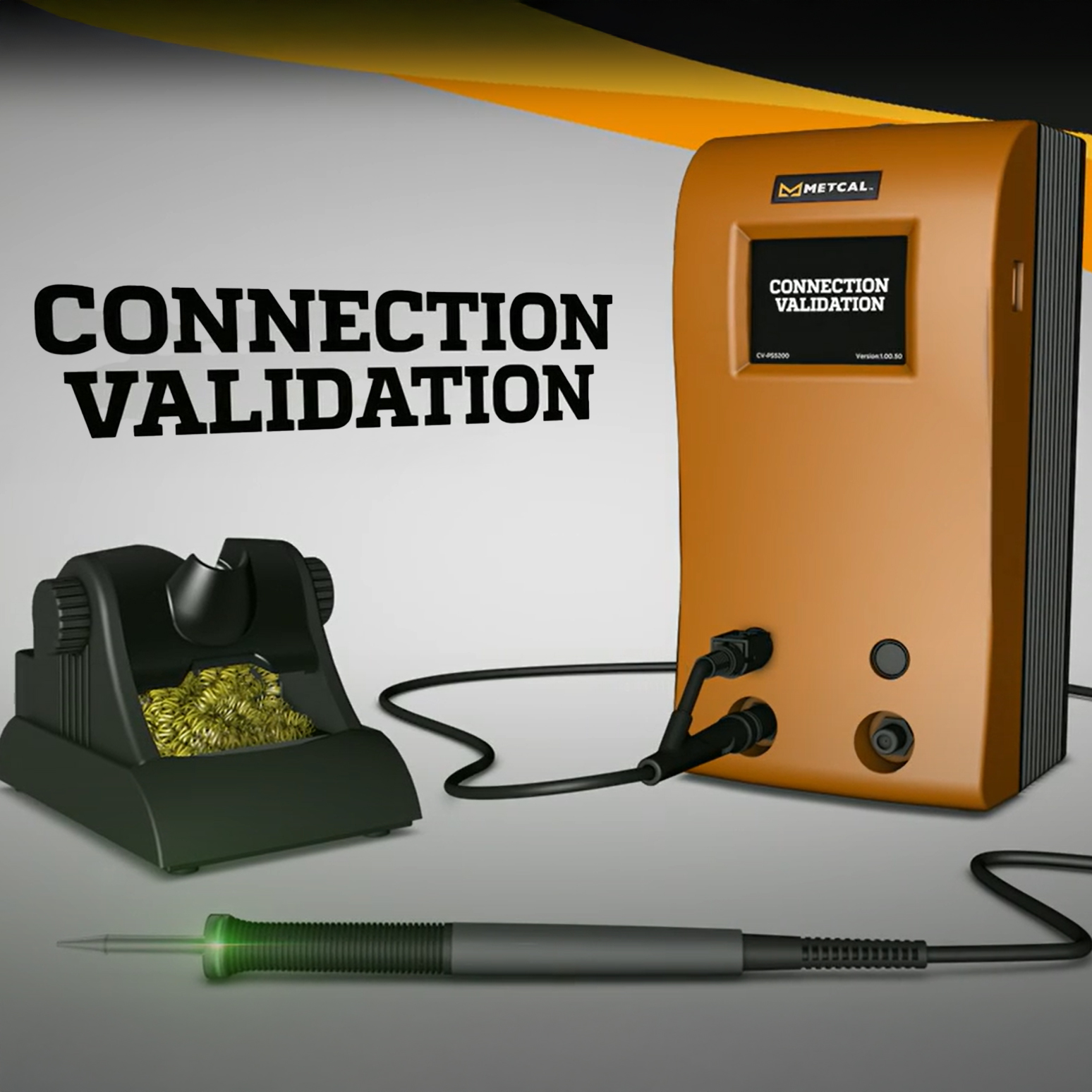

Connection Validation (CV) evaluates the quality of the solder joint by calculating the intermetallic compound formation and provides closed loop feedback to the operator. CV provides feedback to the operator via the LED light ring integrated in the handpiece. It takes the risk associated with the variables involved in the soldering activity and removes the success and failure determination of a good solder joint out of the hands of the operator. CV complements the skill of the operator to judge the quality of a solder joint by introducing an objective method of evaluating solder joint quality. This systemic and objective approach provides repeatability and a measurable standard to the soldering process.

The CV-5200 series features the patented Connection Validation™ IMC formation technology along with SmartHeat® power on demand technology built-in. A 2.8″ colour touchscreen with bold graphics makes programming easy. The integrated net power meter gives a visual representation of the power on demand technology. The CV-5210 is supplied with a CV-H1-AV Advanced Handpiece , compatible with CVC and SMC cartridges and a CV-W1AV Workstand . Other handpieces are available to purchase separately.

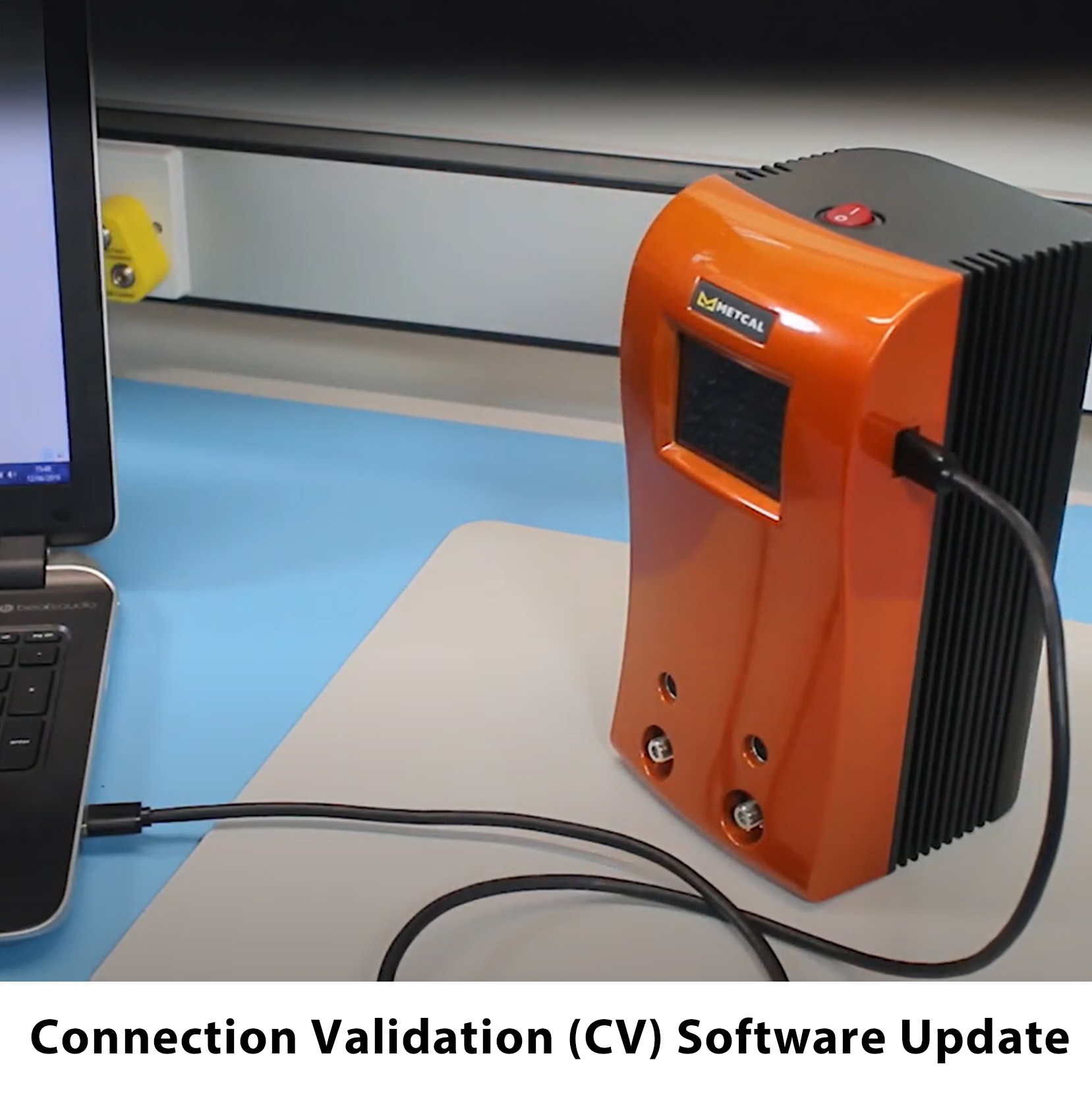

The newly released <a class="qxorange" href=https://www.solderconnection.com/product/cv-iot-gateway-module-desktop-application/CV-IOT Gateway Module works alongside the CV-5210 to provide manufacturers with more soldering data than ever before. Seamlessly monitor all solder joints – not just locally, but from any location on your network and receive information including solder cartridge used, solder temperature and power profiles, dwell time, good and bad solder joint ratings and more, to help improve your process control and efficiency when hand soldering. Available to purchase separately.

Key Product Features & Benefits:

– SmartHeat Power on Demand Technology

– Patented Connection Validation IMC Formation Technology

– 2.8″ colour touchscreen with bold graphics

– Communications Port for process traceability data and firmware graphics

– Integrated Net Power Meter and power graph – With optional precise tip temperature display

– Patented Chip-in-Cartridge technology

– Closed loop bi-directional communication.

– Stores and records cartridge attributes

– Provides traceability information.

– Protects power supply from non-conforming cartridges.

– Backwards compatible with MX series power supplies

– Password protection

– Supplied with a CV-H1-AV Handpiece – CVC & SMC cartridges.

– Full range of handpieces and Upgrade Kits available separately.

– Internal SKU: SS-070-001

Reviews

There are no reviews yet.