MG Chemicals Conductive Paint

MG Chemicals offer conductive paints formulated with solvent-based-acyclic, water-based, epoxy, and urethane binding systems, ideal for use in a variety of applications including prototyping & repairing circuits, ESD Protection and EMI/RFI Shielding.

Conductive Paints

MG Chemicals offer conductive paints formulated with solvent-based-acyclic, water-based, epoxy, and urethane binding systems. Electrically conductive paint is made by mixing an electrically conductive pigment into a non-conductive resin binder. The binder holds the paint together and provides adhesion, while the conductive filler provides the electrical pathway.

Conductive Paints are ideal for use in a variety of applications including prototyping & repairing circuits, ESD Protection, EMI/RFI Shielding and Electroplating Plastics. For advice on your application contact our Sales Office to speak to our technical team.

Choosing the right Conductive Paint.

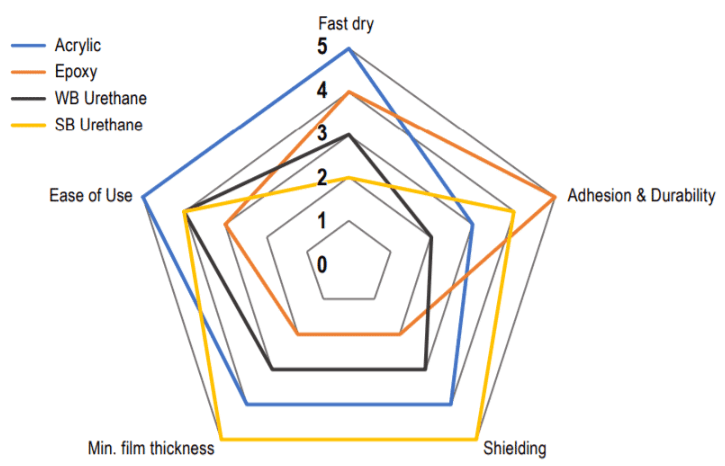

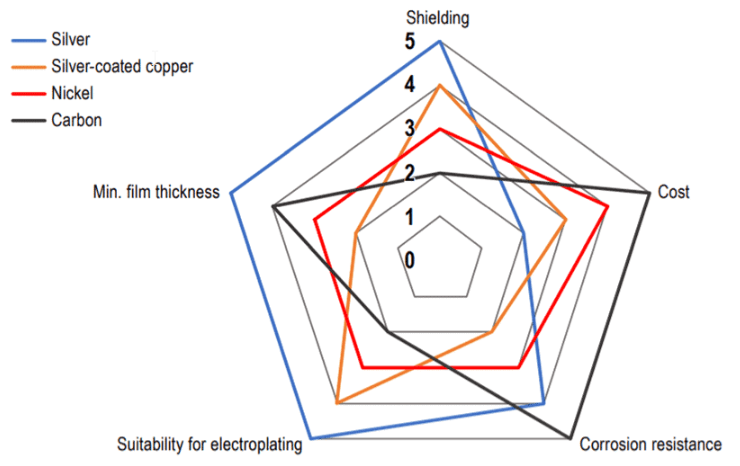

It is important to choose the right combination your specific application as the general properties of conductive paints vary by their binder system and conductive fillers. The graph to the left qualitatively compares the performance of conductive paints based on their binder and conductive filler systems.

Graph 1: Performance comparison of conductive paints based on the binder type. 5 represents the highest performance and 1 represents the lowest performance.

Graph 2: Performance comparison of conductive paints based the filler type. 5 represents the highest performance and 1 represents the lowest performance.