IPC J-STD-001 Certification

Training in the IPC J-STD-001 standard ensures an understanding of materials, methods and verification criteria for exceptional soldered interconnections. For high reliability/critical industries IPC-J-STD-001 Space Addendum training is also available.

What is IPC J-STD-001?

IPC J-STD-001 has become the internationally renowned standard for electronics manufacturing as it is the industrial specification for electronics and electrical assemblies. Training in this standard ensures an understanding of materials, methods and verification criteria for exceptional soldered interconnections.

First released in the 1990’s, there have since been several updates with the most up-to-date covering a thorough explanation from general requirements such as ESD, safety, and tools and then material, components, and equipment, to through-hole mounting, to cleaning and residue requirements.

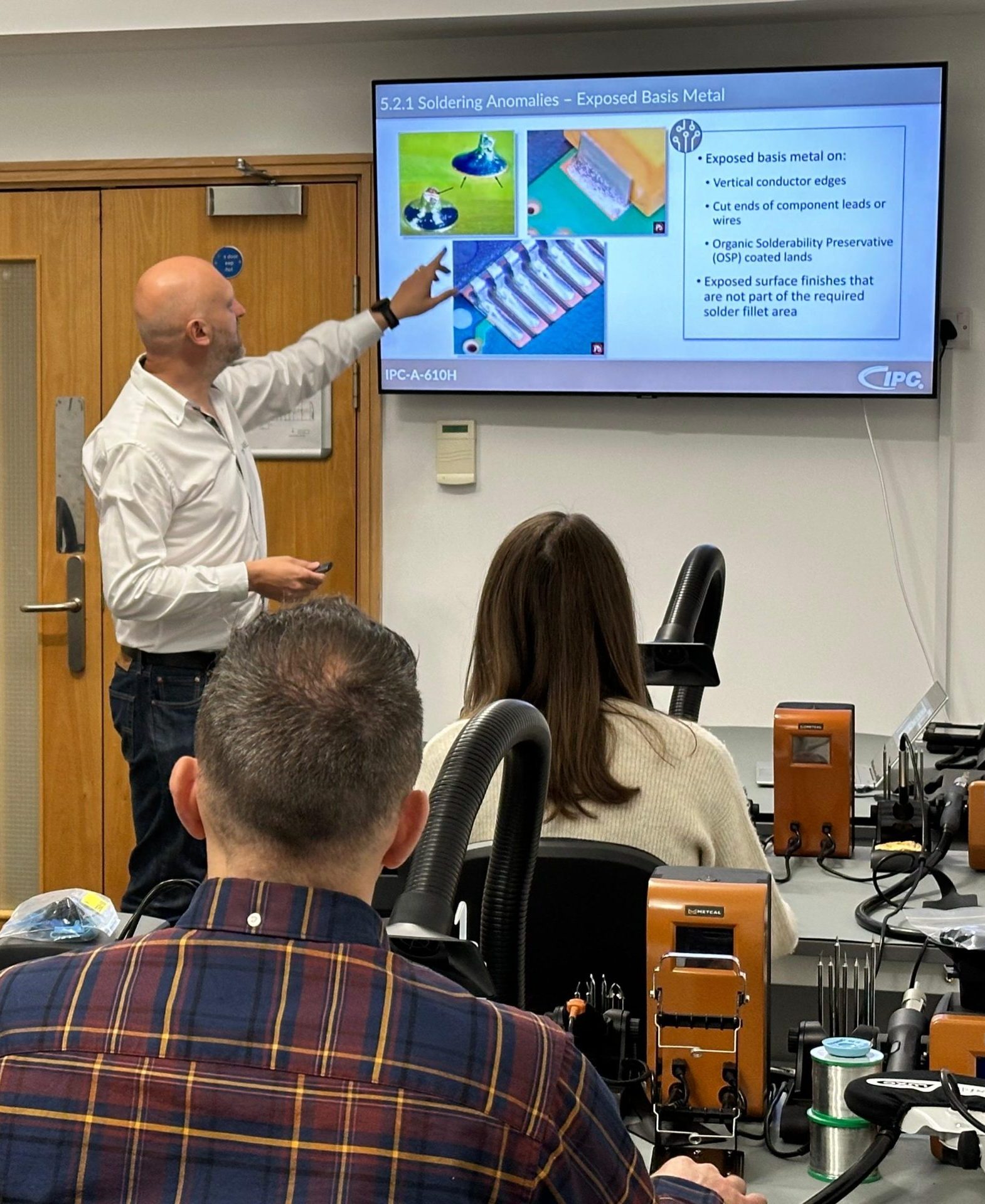

Marq-One’s training course has a practical element that assesses operators’ ability to hand assemble components onto a printed circuit board. This course is crucial for operators involved in the manufacture of PCB assemblies as staying on top of wastage due to scrap, rework, and repair is crucial to safeguarding profits.

The IPC J-STD-001 standard is aimed at those who are soldering electrical or electronic assemblies. Job roles that should consider this training are Assembly Operators, Quality Inspectors, Manufacturing Engineers and Managers and Senior Leaders who need a thorough understanding of the importance of assembly quality. Due to the focus on process control, this standard is also suitable for Quality Assurance roles and Assembly Process Engineers.

There are no specific prerequisites to this course however delegates do need knowledge of industry language and have good soldering skills. This course is not aimed at teaching people how to solder, but making sure delegates know the methods, processes and techniques to solder to IPC standards.

If you’re looking for more basic solder or handling training for your team, please consider Marq-One’s electronics training courses.

Marq-One’s IPC J-STD-001 course covers all three product classes. In particular, the course looks at all aspects of PCB assembly, including plated through hole (PTH), surface mount (SMT), wires/terminal connections and inspection criteria.

While this is not an entry-level soldering course, the basic techniques of soldering are covered through theory and practical sessions. The comprehensive criteria cover what is required to achieve quality and reliable electronic assemblies, and delegates are expected to demonstrate their skills following instruction from the trainer.

The training covers the elements required for producing high-quality PCB Assemblies:

- Wires & Terminals

- Plated Through Hole (PTH)

- Plated Through Hole (PTH) Assembly

- Component Damage

- PCB Coatings, Encapsulation & Staking

Training can be delivered on-site at your business or at Marq-One’s dedicated training centre so you can upskill your team in the most cost-effective way for your business. Practical Assessment kits are provided.

Certificates will be provided on successful completion of the course. The certification course usually takes 3 days and is valid for 2 years. You can recertify within 3 months before expiry but if your certificate expires, you’ll need to take the full course again.

IPC J-STD-001 Space Addendum

The IPC J-STD-001 Space Addendum covers the requirements for specific products that must cope with the rigorous vibration and thermal cycling seen in harsh operating environments found in Space and military applications.

It is a standard for electronics manufacturing organisations who build products for the Space and Defence Industries. This is an advanced course, and it is a requirement that candidates have previously completed IPC J-STD-001 training within 3 months prior to the addendum course.

Marq-One’s training course will take you through not only the materials, methods and verification principles required for high-quality soldered joints but also the value of process control.

The J-STD-001 Space Addendum standard is aimed at those who are assembling circuit board assemblies where the quality of soldered joints is key for those operating in class 3 (High reliability/critical electronic products).

Job roles that should consider this training are those who are involved from a practical perspective, such as Process Engineers, Assembly Operators, Quality Inspectors, and anyone responsible for the accuracy of soldered assemblies, as well as training personnel.

The pre-requisite for the standard IPC-J-STD-001 Space Addendum is that candidates should have completed IPC J-STD-001 within the last 3 months.

Marq-One’s IPC-J-STD-001 Space Addendum course addresses high reliability/critical electronic products e.g. products used in space, military or other mission critical settings.

While this is not an entry level soldering course, the basic techniques of soldering are covered through theory. The course addresses flux, solder composition, soldering to terminals, through-hole, surface-mount devices, and their inspection.

The training covers the elements required for producing high-quality solder joints:

- Materials

- Methods

- Verification Standards

Training can be delivered on-site at your business or at Marq-One’s dedicated training centre so you can upskill your team in the most cost-effective way for your business. Practical Assessment kits are provided.

Certificates will be provided on successful completion of the course. The certification course usually takes 3 days and is valid for 2 years. You can recertify within 3 months before expiry but if your certificate expires, you’ll need to take the full course again.