AIM’s M8 no clean solder paste is designed for the most demanding high density electronic assemblies. An evolution of the highly successful NC258 platform, M8 brings no clean solder paste to the next level. Developed in combination with T4 and finer mesh leaded and lead-free alloy powders, M8 provides stable transfer efficiencies required for today’s challenging applications. A novel activator system provides powerful, durable wetting action accommodating a wide range of profiling processes and techniques.

M8 eliminates HiP defects on BGA and reduced voiding on QFN/BTC components while producing bright shiny solder joints. M8 leaves minimal, high purity, residue, engineered to be safely left in place. Developed with the input of coating and cleaning industry partners, residues can be directly coated or easily removed.

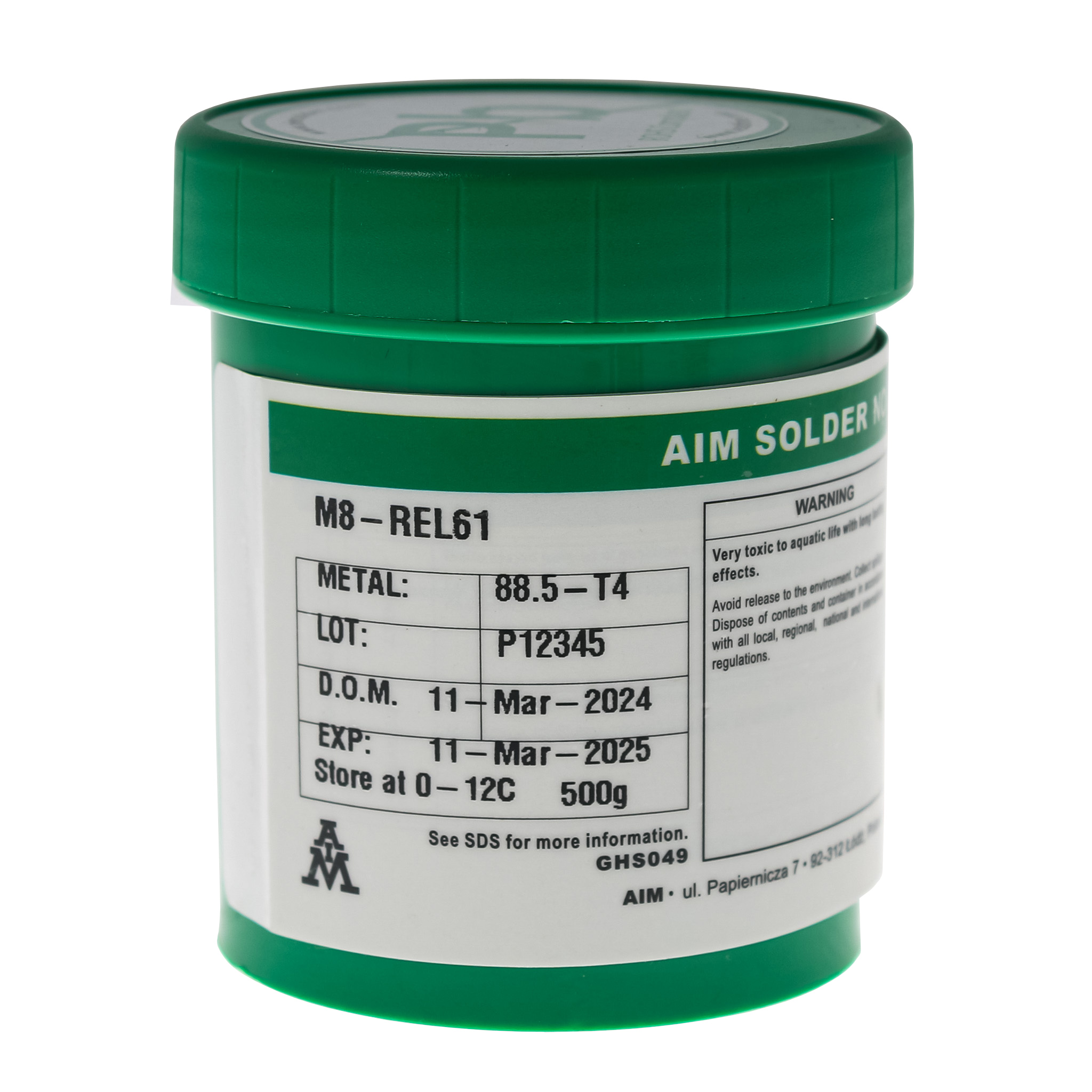

Supplied as standard in lead-free alloy SAC305 as well as AIM’s specialist High Reliability alloys REL61™ and REL22™. These have been developed to meet the demands of an evolving solder market. Greater durability, lower costs and lower processing temperature are key drivers and AIM REL61 and REL22 provide assemblers with new tools to improve product quality in the assembly process. REL alloys have demonstrated reduced tin whisker formation as well as outperforming SAC alloys in thermal shock, vibration and drop shock resistance, making these alloys the ideal choice for all electronics applications.

For leaded alloys please click here.

Key Product Features & Benefits:

– Capable of 200µm deposits

– Low Voiding: <5% on BGA and <10% on BTC Components

– Eliminates HiP Defects

– REACH and RoHS Compliant (Lead-Free)

– Powerful Wetting on Lead-Free Surface Finishes

– Passes Bono Testing

– Available in REL22™, REL61™ & SAC305 Alloys

– ROL0 per IPC J-STD-004 and ROL1 per J-STD-004B (3.3.1)

AIM’s Product Range available from the Solder Connection throughout Ireland and Northern Ireland only.

Reviews

There are no reviews yet.