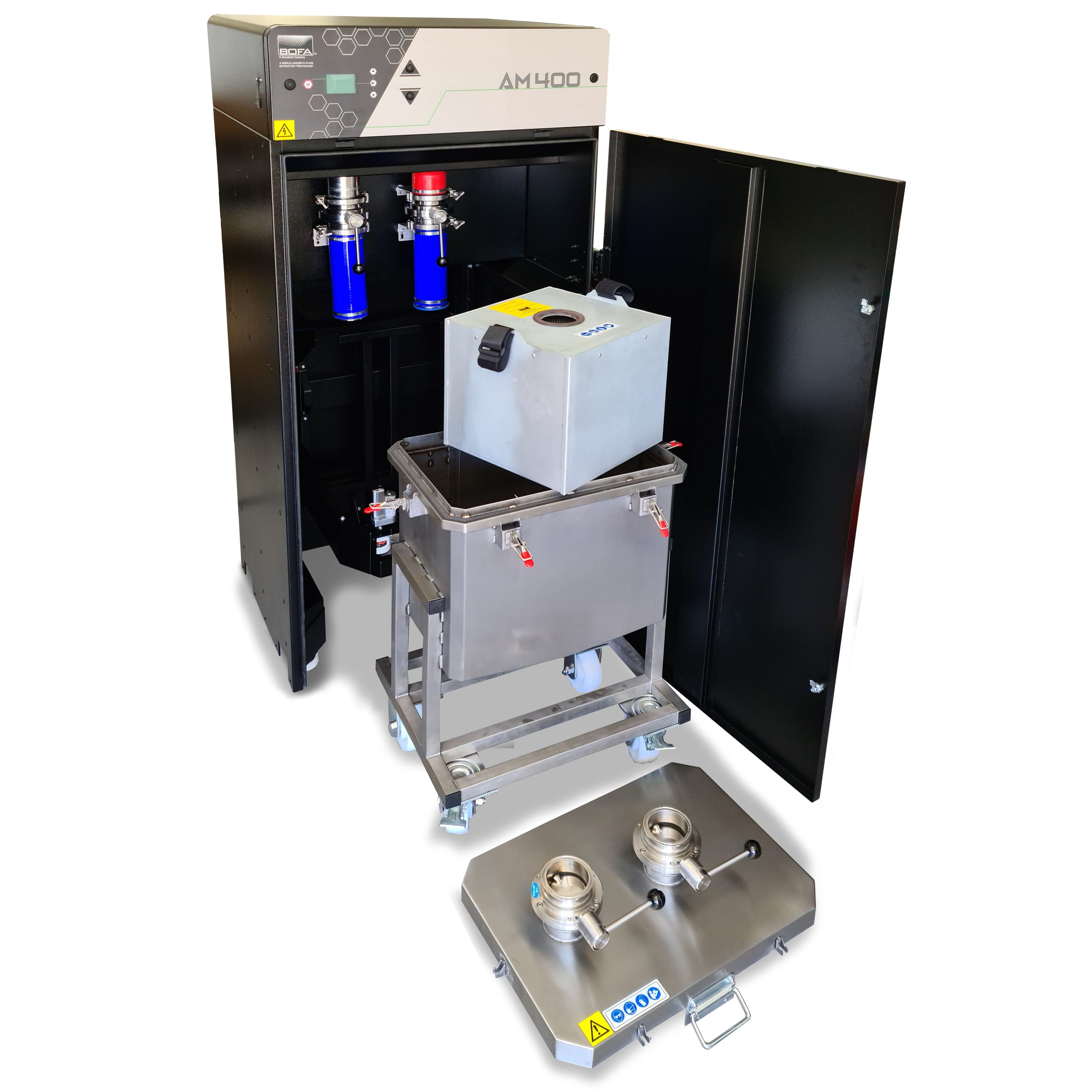

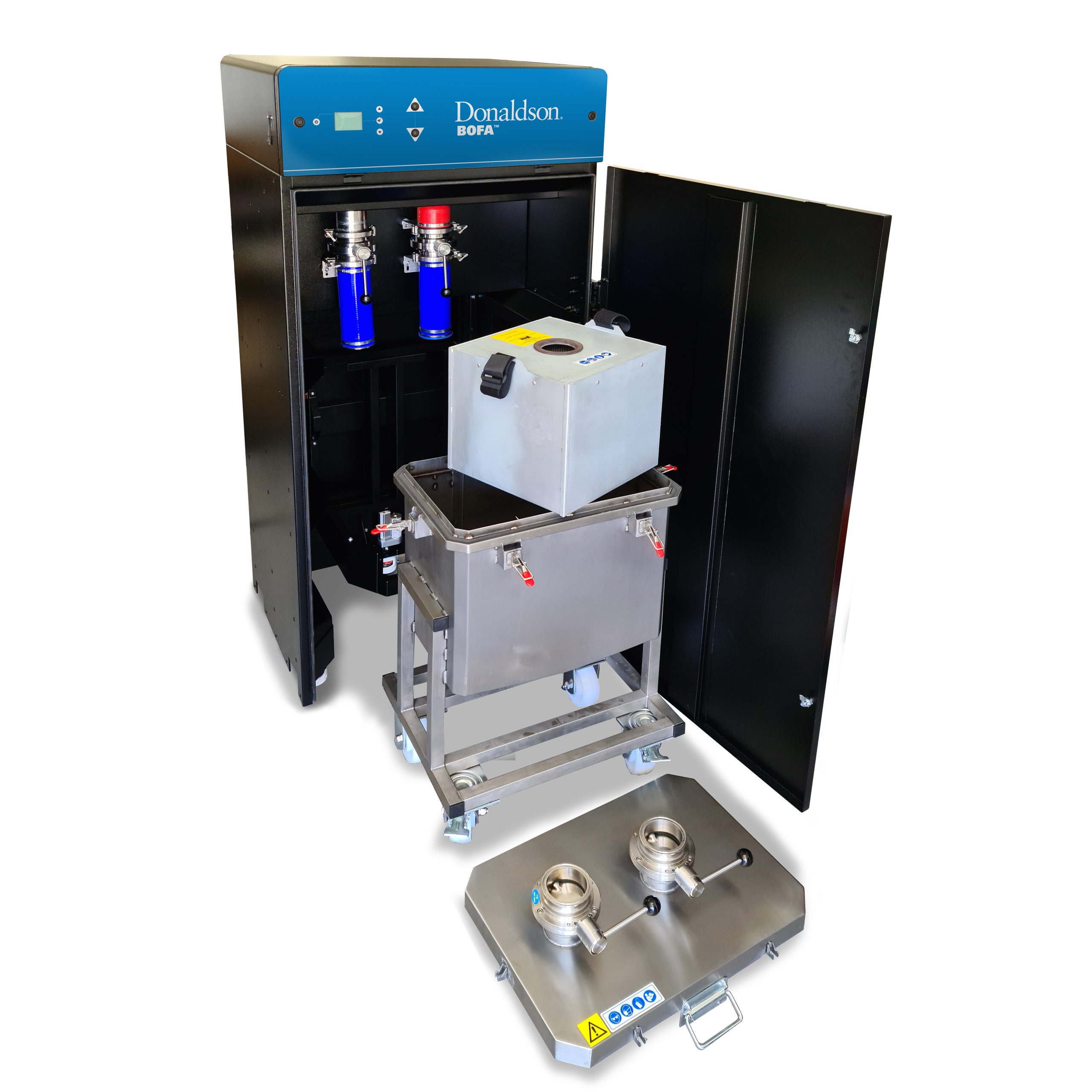

Donaldson BOFA’s AM 400 is designed and built specifically for inert particulate filtration, making it the premium extraction solution for the additive manufacturing industry. The AM 400 is suitable for a full range of industries including Pharmaceutical, Nuclear, Aerospace, Aeronautical, Medical & High-value metal printing. It particularly offers benefits to users in direct metal laser sintering and selective laser melting polymer applications.

The AM 400 extraction system is a world-first in additive manufacturing fume extraction making the exchange of filters in powder bed fusion processes safer, faster, and better for productivity. The system offers high airflow potential, up to a maximum of 190 cu ft/min and a maximum operating pressure of 250mBar, with low leakage at <30 ml/min @ -10mBar. Designed and built specifically for inert particulate filtration, the AM 400 is a premium extraction solution for the additive manufacturing industry. It offers significant benefits to users in direct metal laser sintering and selective laser melting polymer applications.

The AM 400’s filters are contained inside a separate housing and sealed. Each filter change can be completed safely and quickly, in a location remote from the process floor. The filter housing is completely removable, and the whole procedure can be performed on-site with minimal disruption. As fine powders used in metal 3D printing bear potential risk of ignition when exposed to oxygen, the printing process generally takes place in a sealed build chamber filled with inert gas. Filtration systems are usually attached to the printer, and changing filters requires shutting down, disassembling the whole unit, and moving it to a safe location. That is not the issue with the AM 400 system, which ensures efficient air filtration combined with safe operation and greatly reduced downtime leading to increased productivity.

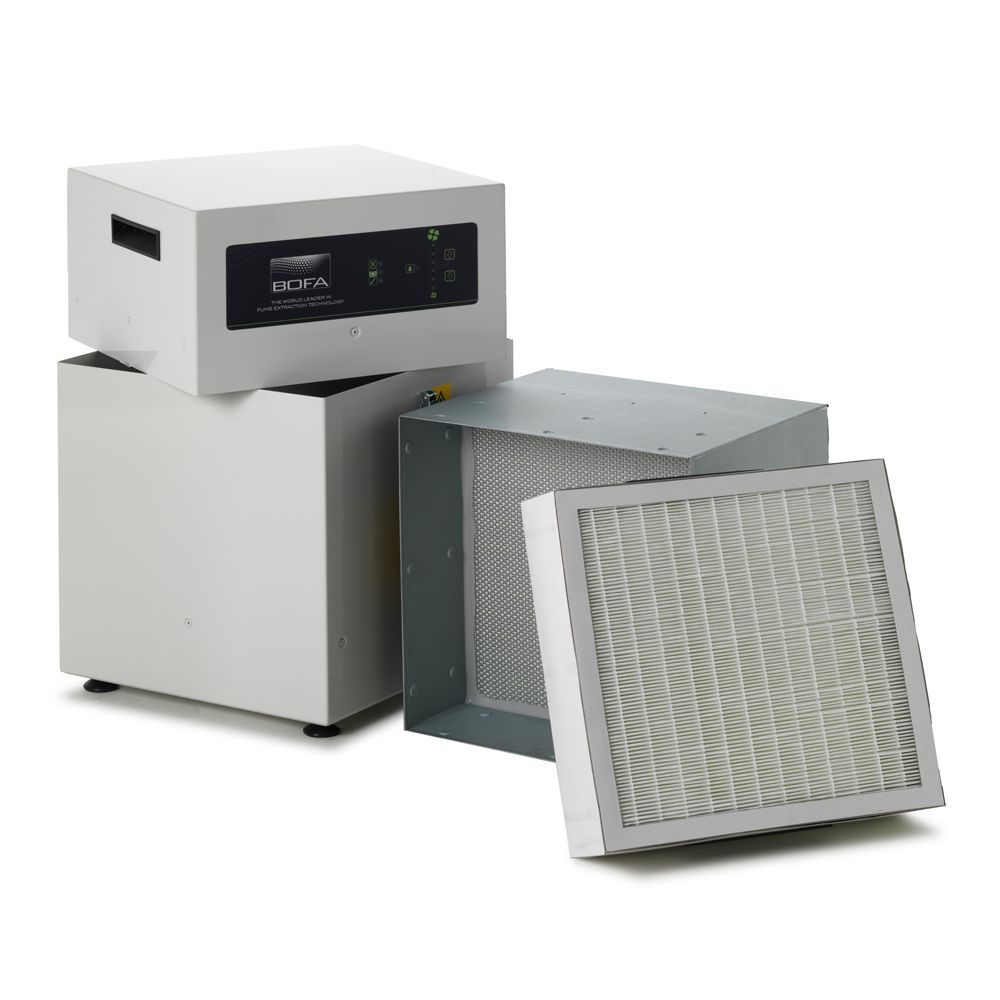

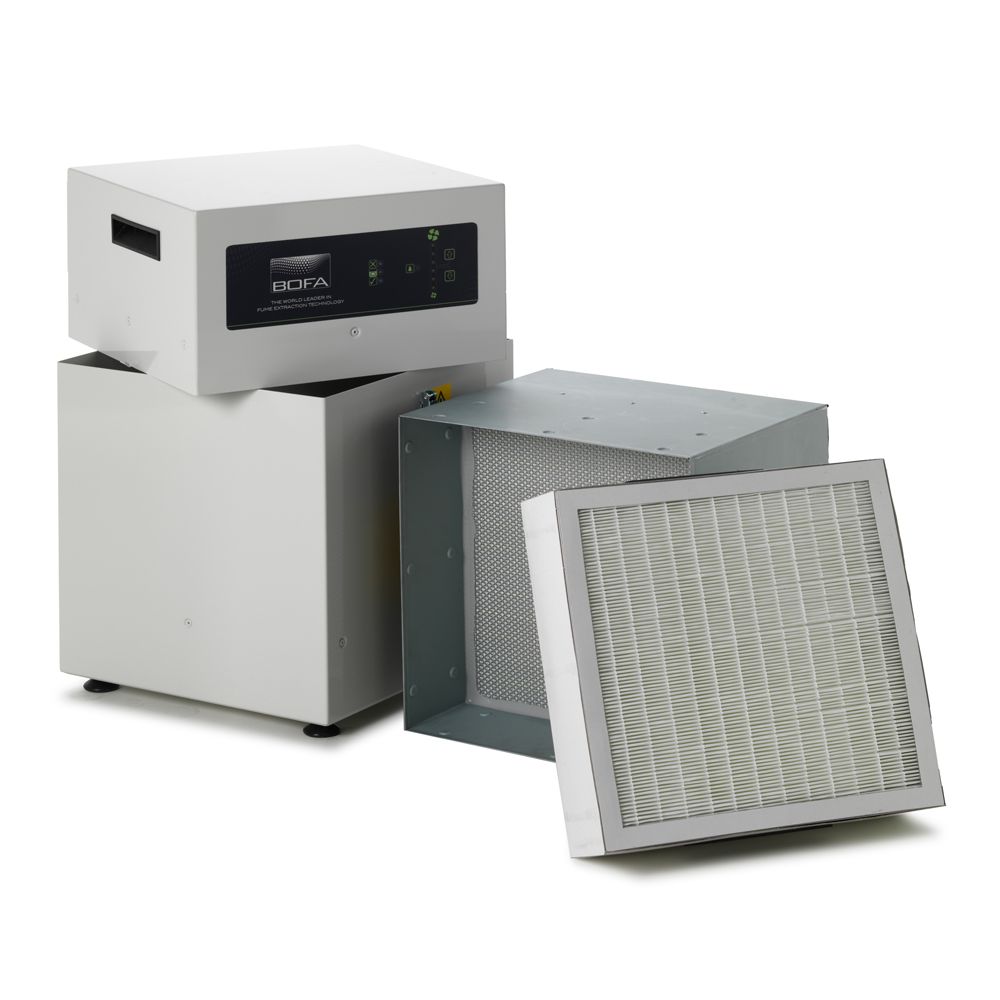

The AM 400’s high-surface-area patented DeepPleat DUO filter delivers key benefits including, Clean chamber environment, Clear laser lens, Higher quality process & Protected equipment. This system is available with two filter options:

– A1030460 Main Filter: F8 Filter supplied as Standard with a filter efficiency of 95% @ 0.9?m

– A1030462 Main Filter: Optional H14 Filter for applications producing very fine particulates where a higher level of filter efficiency is required (Filter efficiency of 99.997% @ 0.3?m).

The AM 400 features Donaldson BOFA’s innovative, patented iQ System, which provides versatile reporting and control for fume extraction.. The iQ status indicator offers on-screen system alarms and easy identification of system performance. With this intelligent system, users can also download log files to examine issues after the event. The AM 400 is also equipped with a remote start / stop feature, which ensures the extractor turns on or off with the host unit – users don’t have to think about separate operation of the power as this is handled automatically.

This new and innovative extraction solution was developed in partnership with a leading additive manufacturing company and specifically designed for powder bed fusion applications. The AM 400 is part of Donaldson BOFA’s significant investment in AM solutions, providing long filter life and a leak-proof sealed extractor. It delivers a range of benefits for OEMs in the 3D metal printing sector. Solder Connection, in conjunction with Donaldson BOFA, can also work in partnership with customers to create a customized solution.

For more information, to discuss how the AM 400 may suit your application or to request a quotation please contact our Sales Office.

Key Product Features & Benefits:

– Increased productivity: Long filter life & Quick filter change procedure

– Increased safety: Low leakage, Isolation valves & Removable filter housing

– Greater process control: Constant flow rate using iQ system, Better capture through high performance pump, Low leakage (low O2 ppm) & High flow rates

– More system information: iQ filter monitoring, On-screen system information, Remote diagnostics & System alarms

– Lower cost of ownership: Low leakage (reduced argon spend)

– Improved communication: Interfacing capabilities from iQ system

– Ease of use: Simple filter change procedure, Ergonomic design & Lift assist

– Internal SKU: FE-050-078

Reviews

There are no reviews yet.