AIM’s RX18 no clean flux core wire solder was developed to provide excellent soldering results with all alloys and surface finishes. Engineered for robotic soldering, RX18 promotes thermal transfer, fast wetting, and rapid solder penetration into plated through holes or surface mount interconnections. RX18 specialized packaging ensures consistent, accurate, jam-free wire feeding. RX18 post solder residues are minimal, clear and pass IPC-004A and IPC-004B SIR and corrosion requirements and do not require cleaning.

RX18 is available in AIM ‘s High Reliability Lead-Free Alloys, REL61™ and REL22™. These have been developed to meet the demands of an evolving solder market. Greater durability, lower costs and lower processing temperature are key drivers and AIM REL61 and REL22 provide assemblers with new tools to improve product quality in the assembly process. REL alloys have demonstrated reduced tin whisker formation as well as outperforming SAC alloys in thermal shock, vibration and drop shock resistance, making these alloys the ideal choice for all electronics applications.

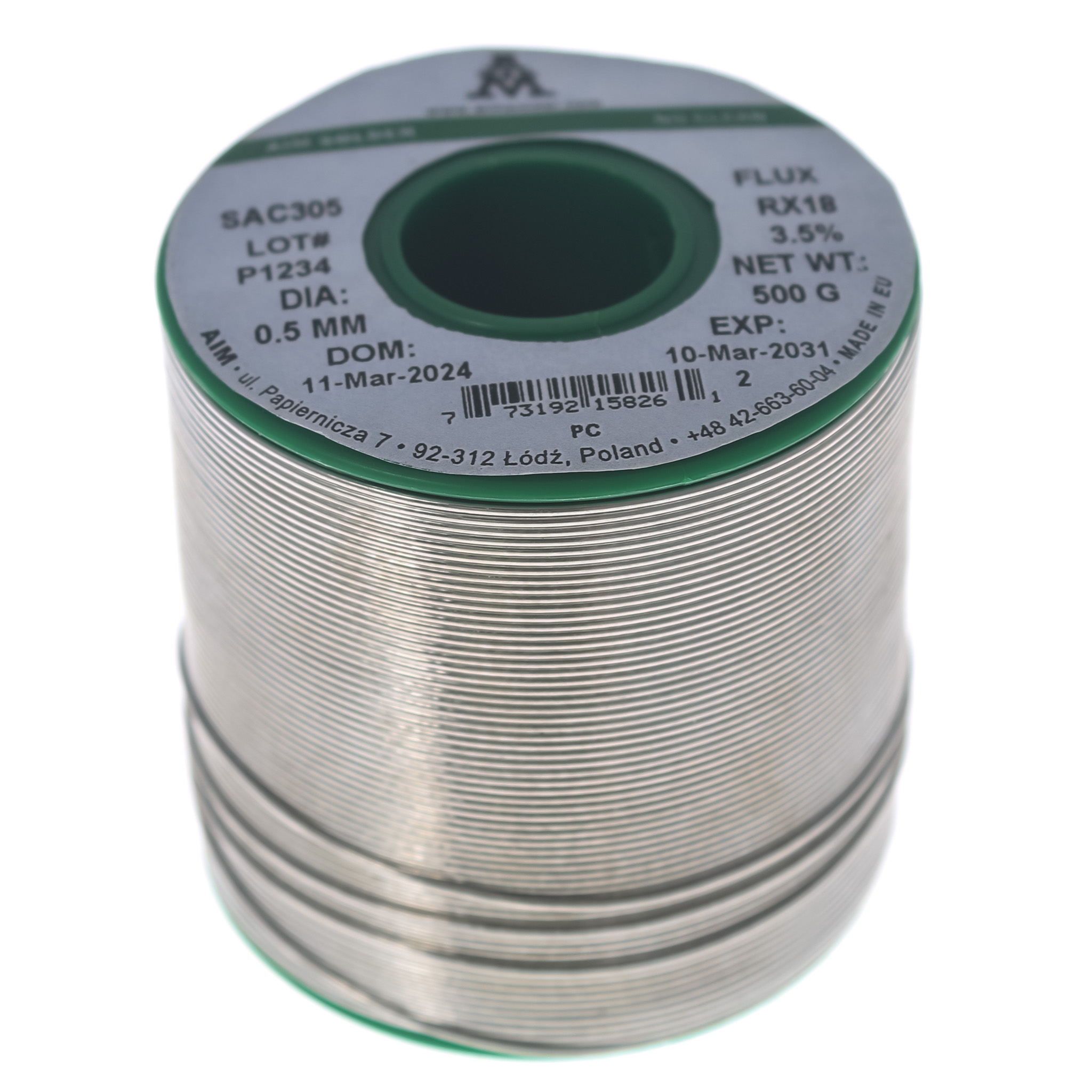

Key Product Features & Benefits:

– Supplied in a range of lead-free alloys including REL22™, REL61™, SAC305 and SN100C (Other lead-free alloys and lead based variants may be available on request.

– Supplied on a 500g Reel

– No Clean Flux Formulation (3.5%)

– Low Voids/Skips

– Low Spatter

– Extends Solder Tip Life

– Fully REACH and RoHS Compliant.

– Fast Wetting/Feed Rates

– Halogen Free per EN14582

– Meets J-STD-004B

– Flux Classification: ROL0

AIM’s Product Range available from the Solder Connection throughout Ireland and Northern Ireland only.

Reviews

There are no reviews yet.