Rework

When undertaking rework or repair of PCB’s it is important to ensure that the correct Equipment,

Solder & Fluxes are used so that the reworked boards can be used within future production.

Rework

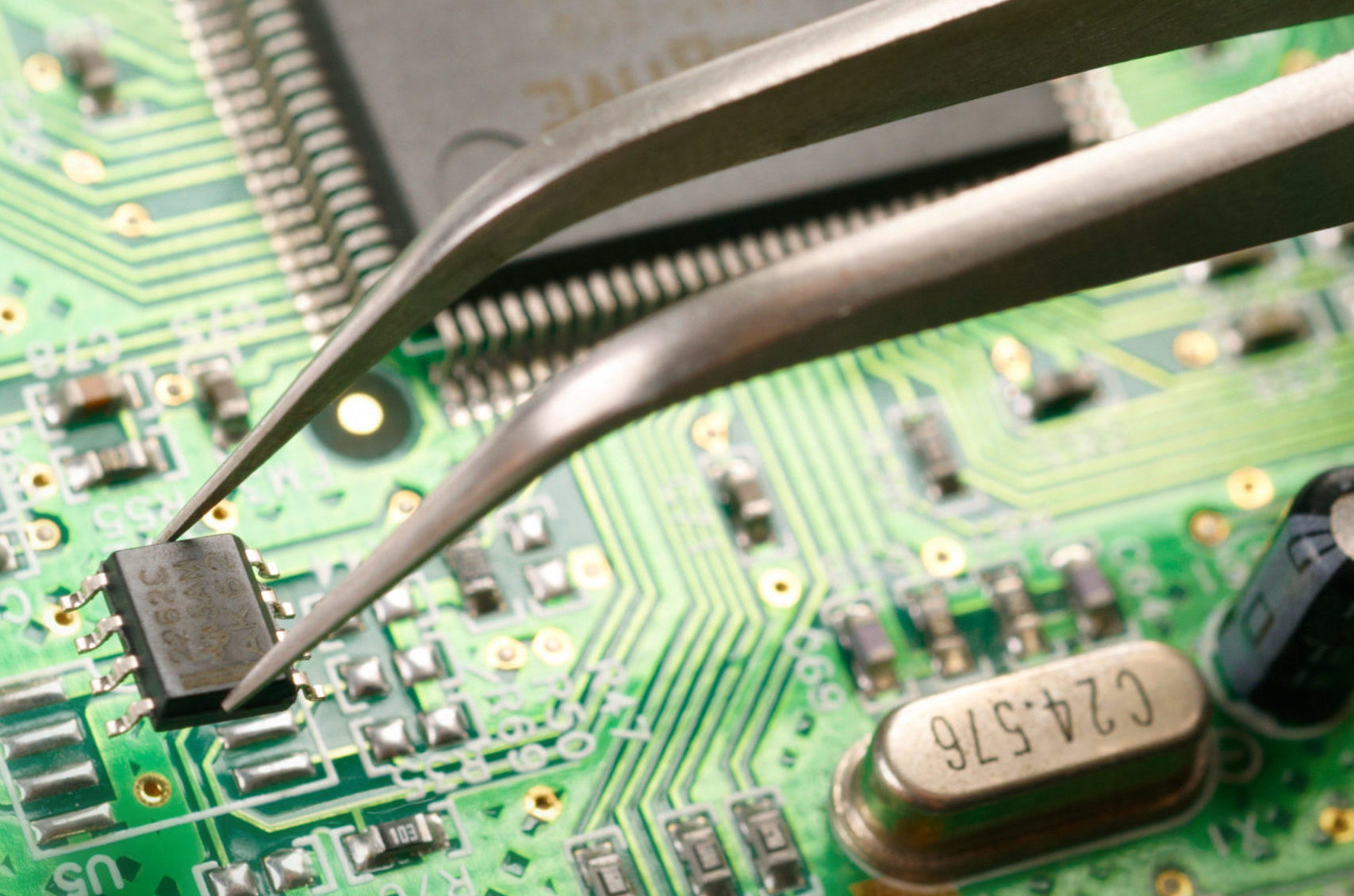

It is highly unlikely that soldering will produce perfect results on every board, with even the high quality components failing on occasion. Rework is the term used for the refinishing or repair of PCB’s within electronics manufacturing, completed by desoldering and re-soldering of the boards components.

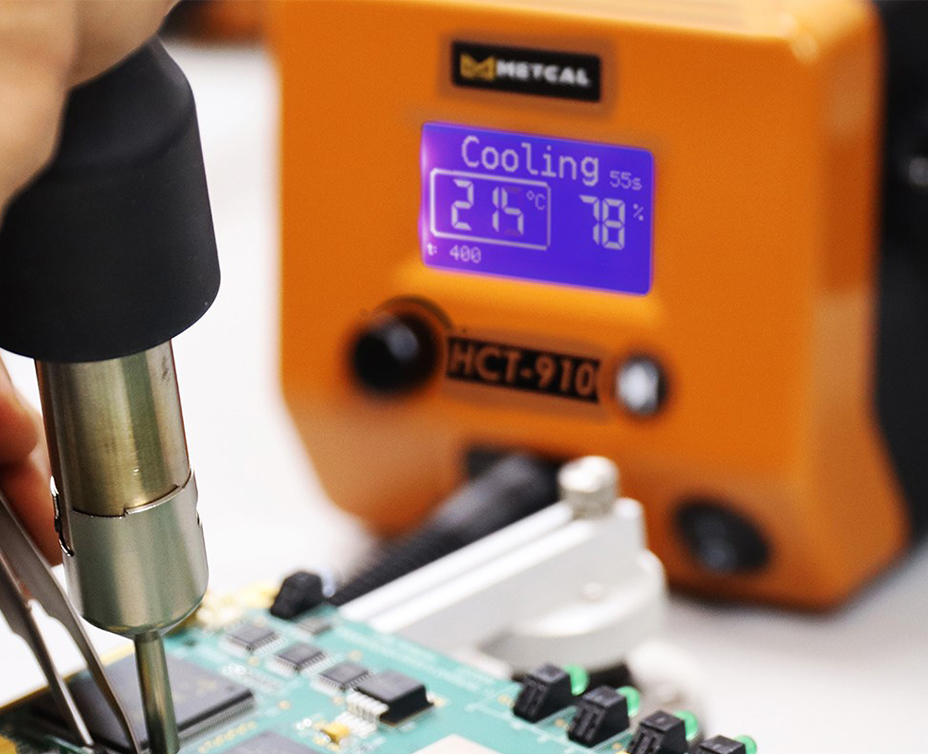

Solder Connection supplies a range of products designed for rework applications including Metcal Soldering Irons and Hot Air Convection Systems, which ensure quality results when repairing or reworking boards. Metcal’s wide range of component removal soldering tips and tweezers will aid in eliminating the possibility of any board damage. To further support your rework processes a comprehensive range of fluxes, wires, de-solder braids, ESD products and cleaning solutions are avilable.

Rework in Electronics

Reworking is completed throughout electronics assembly and is a standard practise amongst most Electronics companies today. It is important to ensure that the correct Equipment, Solder & Fluxes are used within the process so that the reworked boards can be used within future production. Failure to do so may damage the board or components, affecting the product and becoming an expensive write off.

Rework situations vary, so it is essential your hot air tool includes precise and simple temperature and flow rate control. Metcal’s new HCT-910 Hot Air Rework Station includes ‘On-the-fly’ manual control which allows the operator to adjust, control, and quickly toggle between temperature and airflow. This, in combination with accurate temperature, and 900W heater performance, improves throughput while controlling a tight quality process.