Wave Soldering

Solder Connection provides a range of Solder Alloys, Solder Fluxes, Wave Pallets, De-Drossing Tools

and Profiling Equipment designed for use during the Wave Soldering process.

Wave Soldering

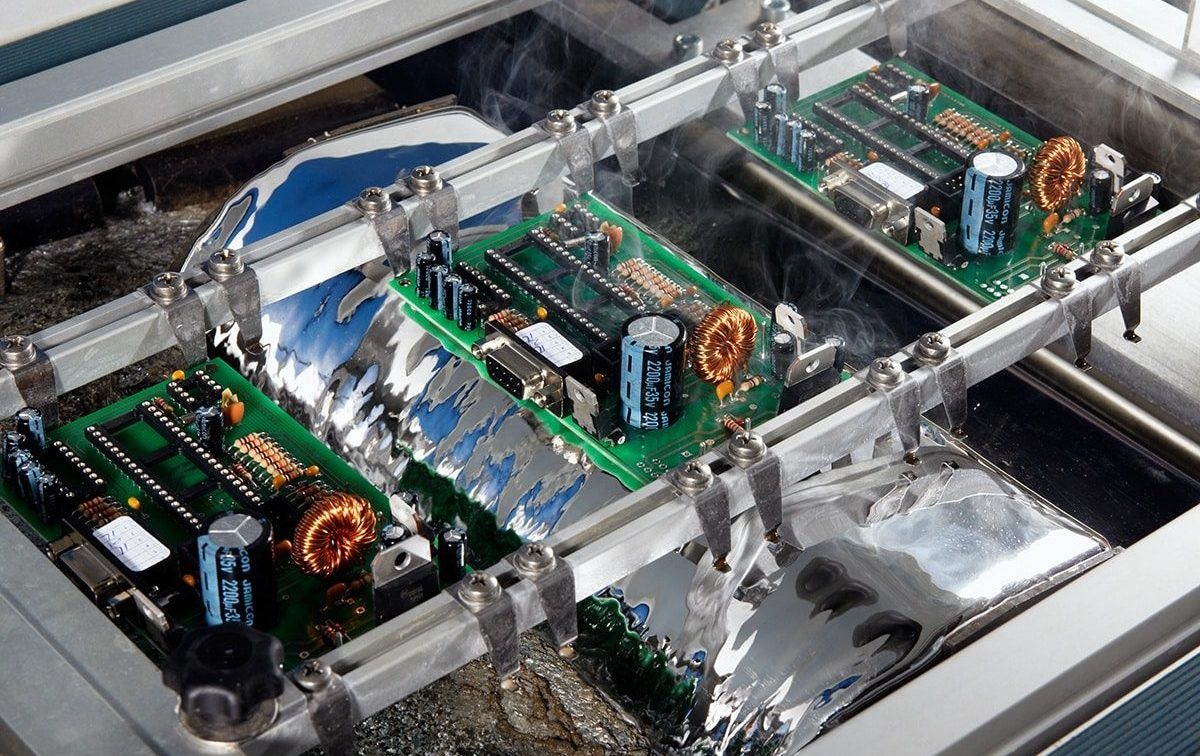

Wave Soldering is used to quickly and efficiently solder fully assembled printed circuit boards in volume production environment. During Wave Soldering a PCB is treated with flux, preheated and then passed over a wave of molten solder.

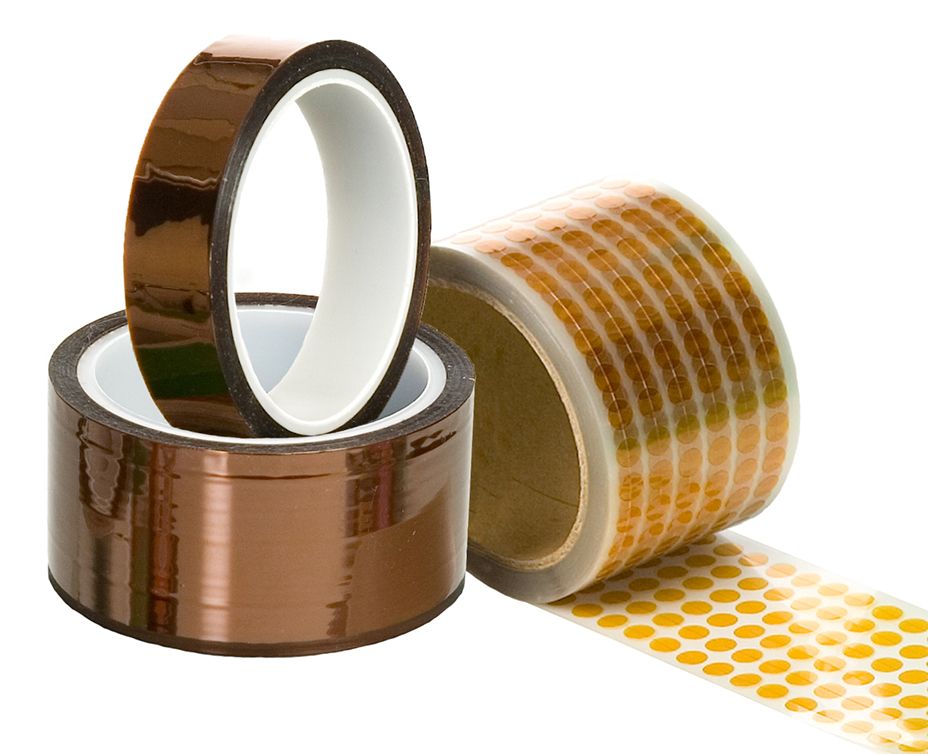

Solder Connection provides a range of Solder Alloys & Solder Fluxes, designed for use during the Wave Soldering process. To further aid manufacturers, a PCB Assembly Tooling service is offered. This allows for the design & manufacture of wave solder pallets, used to hold PCB’s when transporting over a wave. A full range of Profiling Equipment and De-Drossing tools for general maintenance as well as an extensive Solder analysis service are also available.

Solder Dross Recycling

Solder dross is a by product of the wave soldering operation which is created by the molten metals exposure to oxygen. The dross is a combination of solid metal and an oxide which also contains metal for recycling.

Solder Connection, provides a complete recycling service for all your Tin-Lead and Lead Free solder dross and solid pot metals. All dross and pot metal should be segregated by alloy as it will yield the highest rate of return for your company.